Stone columns refer to solid or hollow cylindrical architectural decorative elements crafted from marble or granite. Depending on the type of stone used, they can be classified into marble columns and granite columns. In terms of the column's outer shape characteristics, they can be categorized as Roman columns, plum blossom columns, twisted columns, railing columns, carved columns, multi-faceted columns, as well as single-color and multi-color columns. Based on the cross-sectional dimensions, they can be further divided into equal cross-sectional diameter columns, conical columns with unequal cross-sections, and drum-shaped columns.

The distinction between stone columns and arc-shaped plates lies in the fact that arc-shaped plates are merely used to wrap and decorate the outer surface of the column, being a part of the cylindrical surface; whereas stone columns are solid or hollow complete cylindrical structures or assembled cylindrical columns.

Types of Common Cylinders

The common cylinders discussed here mainly refer to those with straight or curved generatrix lines but circular cross-sections, which can be equal or unequal in section, such as equal diameter cylinders, conical cylinders, drum-shaped cylinders with smaller diameters at both ends than in the middle, and railing columns, etc.

The diameter and height of common cylinders primarily depend on the dimensions of the rough stone. The minimum diameter is generally 100mm, and the maximum diameter is less than or equal to 2000mm. Whether it is a complete or partial cylinder, the height of a single piece is usually less than 5000mm, although there are some special cylinders with heights exceeding 5000mm. A standard stone column includes three parts: the base, the shaft, and the capital.

Processing of Common Cylinders

1. Polishing of Cylinders

The polishing of cylinders is generally carried out on a lathe equipped with an air or hydraulic pressure grinding head. The grinding material installed on the grinding head can be quickly replaced. The grinding material for polishing cylinders is usually annular, using the end face to contact the cylinder and employing a linear polishing method.

Since the grinding force during polishing is much less than the cutting resistance during shaping and cutting, when clamping the cylinder for polishing, only a center hole support is needed at the headstock end.

Depending on the material of the stone being polished, the gradation of the polishing material also varies. For instance, when processing granite, five different grades of roughness can be used for the polishing material, while for marble, dddhhha certain typedddhhh of polishing material can be employed.

Due to the significant undulations and variations in the contour lines of products such as railing columns and vases, it is difficult to polish them using the aforementioned annular grinding material. Therefore, currently, manual polishing of irregular rotary bodies using simple polishing equipment is still utilized to complete the polishing of products like railing columns.

2. End Face Cutting

After the polishing of the cylinder is completed, a diamond saw blade can be used to cut the two end faces of the cylinder, ensuring that the length dimension meets the finished product requirements.

It is important to note that the angle between the cut end face and the axis should be slightly less than 90 degrees, so that the joint can be small and aesthetically pleasing during installation.

3. Cleaning, Inspection, and Packaging

Once the cylinder has been processed, it can be packaged after being cleaned, inspected, and dried. The packaging of the cylinder is divided into two steps: first, the cylinder is wrapped with a 0.5mm thick plastic film, and then it is placed into a wooden frame for fixation. Care must be taken to prevent damage to the cylinder during packaging and transportation.

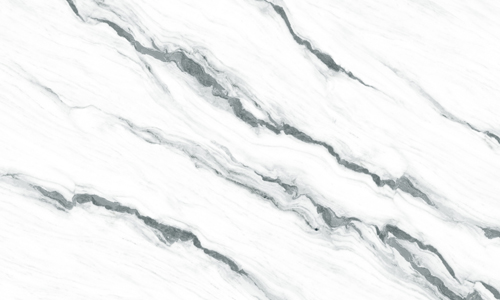

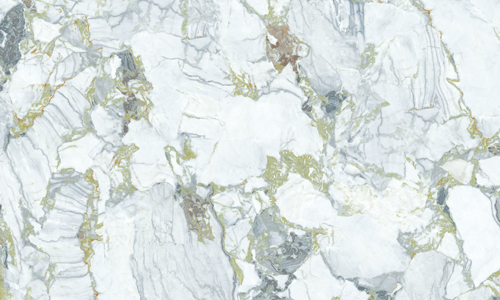

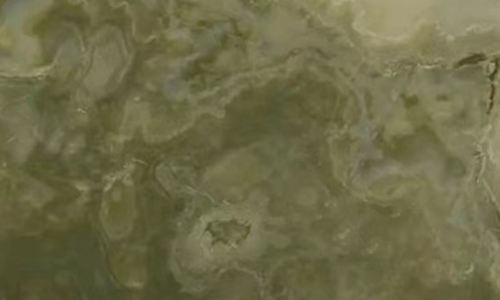

Marble Column Case Images

Lillian Fortune East Stone

📧 Email: sales05@fortunestone.cn 📞 Phone: +86 15960363992 (Available on WhatsApp) 🌐 Websites: www.festonegallery.com | www.fortuneeaststone.com